Established on December 28, 2021, SAMA was founded with a vision to not only become a manufacturing benchmark but to drive the growth of Mozambique's industrial sector. Headquartered in Maputo, our factory is strategically located in the Matutuine district, adjacent to major cement factories and transport hubs.

We deliver high-performance, durable, and sustainable packaging solutions supported by advanced production systems and rigorous quality control. Our commitment to precision manufacturing and continuous improvement ensures consistent, world-class standards that reliably serve the needs of the construction, agricultural, and chemical industries.

Shortest delivery times for local cement & agri industries.

Fully integrated Starlinger machinery ensures consistency.

Specialized in heavy-duty sacks.

Investing in water, power, and education for Matutuine.

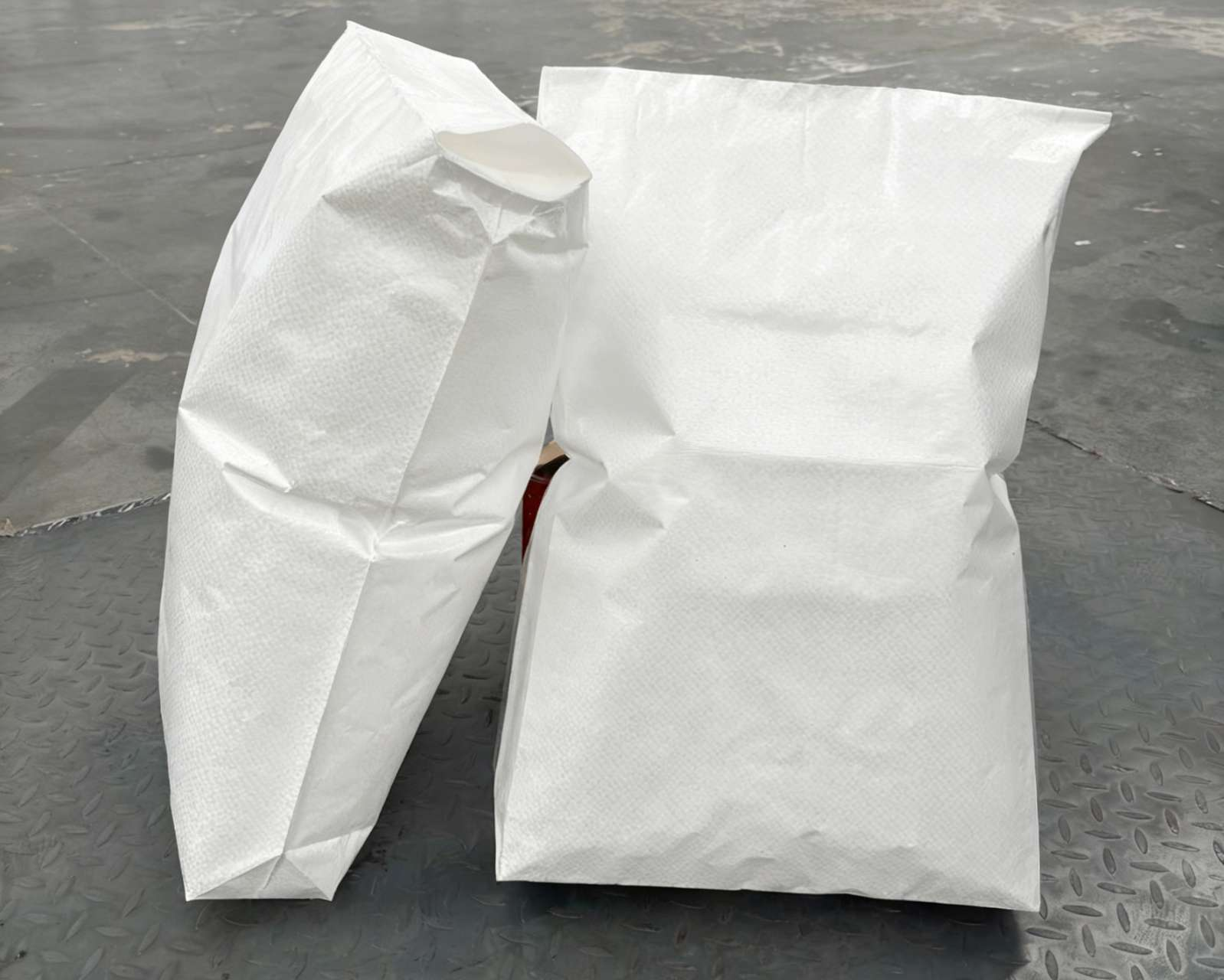

We offer a complete range of PP woven packaging designed for strength and stability.

End-to-end production control using Starlinger machinery.

This is where the sack production process begins. At SAMA, we utilize advanced extrusion technology, including the Starlinger starEX 1600 system, to produce high-quality tapes that form the foundation of our woven sacks. Our extrusion process ensures stable performance, high production speed and excellent material efficiency, enabling the consistent manufacture of light yet strong tapes with reliable dimensional accuracy.

At SAMA, we enhance production efficiency and fabric quality through advanced Starlinger stacoTAPE technology, ensuring precise tape winding and optimal preparation for high-performance weaving. Integrated control systems allow accurate length control and smooth bobbin changes, resulting in consistent fabric quality, superior uniformity and reliable sacks that meet demanding industrial standards.

Our woven fabrics form the foundation for a wide range of packaging applications, including sacks, big bags, tarpaulins and agricultural textiles. At SAMA, we combine advanced production technologies with cost-efficient manufacturing to achieve high-performance weaving, ensuring excellent precision, stable productivity and consistent quality. This allows us to deliver eco-friendly packaging solutions.

Our woven sacks are designed to provide reliable protection against moisture and dust while delivering high-quality, visually appealing printing. By utilising advanced coating and lamination technologies, we enhance both the functional performance and aesthetic value of our products. These solutions are suitable for tubular and flat woven fabrics, offering improved durability and superior sealing performance.

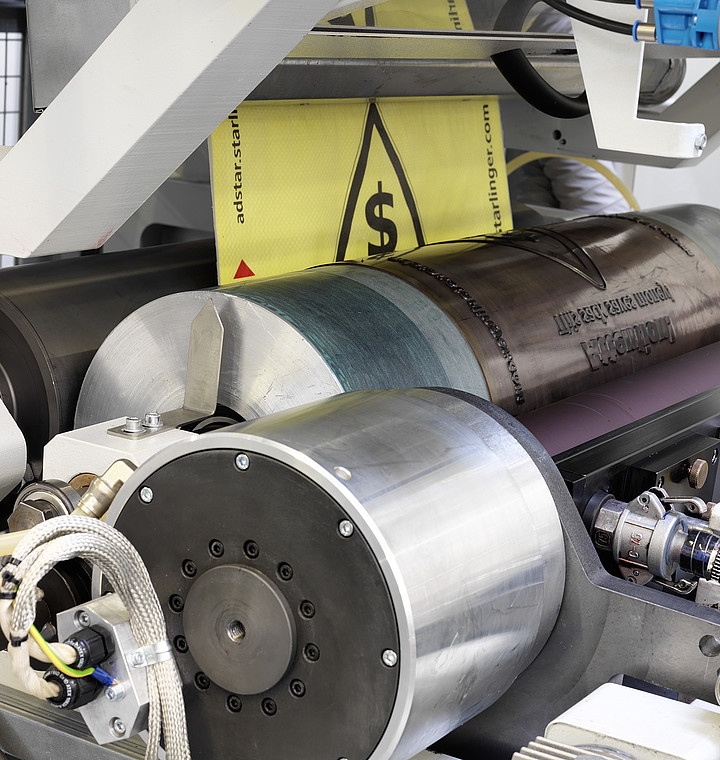

An effective product presentation must be eye-catching – and our advanced printing systems make this possible. Through high-quality flexographic printing technology, we ensure that your woven sacks stand out with sharp graphics, consistent colours and a professional finish. Our printing capabilities enable your products to differentiate clearly from competitors and strengthen your brand presence in the market.

Whether sewn or welded – our conversion lines produce the sack you need, utilising advanced Starlinger technologies such as starKON and multiKON to ensure exceptional performance and reliability. Our production not only achieves high speed and superior quality, but also operates with lowest energy consumption and minimum production waste – clearly prioritising sustainable and efficient manufacturing.

Woven plastic sacks are a valuable secondary resource, and at SAMA we integrate recycling into our production process to maximise material utilisation and minimise waste. Production scrap is collected and efficiently reprocessed for reuse, reducing raw material consumption and lowering waste handling costs. Through recyclable design principles and continuous process improvement, we support a closed-loop packaging system.

Build your future with Mozambique’s manufacturing leader.

At SAMA, Strength Starts Here — empowering local employment, growing future talent, and advancing sustainable manufacturing.

Values:

- Safety First

- Technical Excellence

- Community Respect